Created by Ukrainians: How 3D printing helps the Ukrainian military

And how the production is running now

In the eighth month of the full-scale war, technology companies are trying to help Ukrainian defenders. Particularly, owners of 3D printers use them to manufacture components and accessories for weapons and medical means. 3D Tech ADDtive is one of such companies. What exactly does the team do for the Armed Forces of Ukraine? How did it expand its manufacturing? And what logistical problems did it face? Mykhailo Shulgan, Chief Operating Officer of the Ukrainian company 3D Tech ADDtive, told Mind about this and much more.

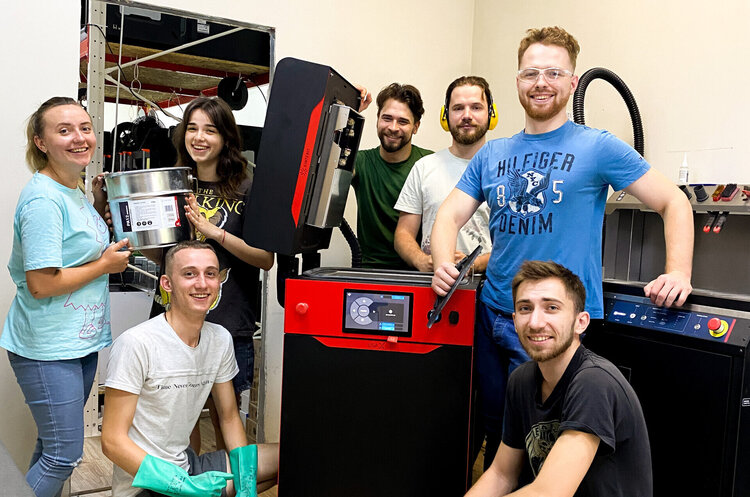

What was their start? 3D Tech ADDtive was founded by two brothers Petro and Pavlo Yesyp. The history of the company began in 2017. Then the founders began to create the first workspace in the format of a 3D printing bureau. "The company started with one printer. As we grew, new equipment appeared. We bought printers one after another," Shulgan recalls.

Now 3D Tech ADDtive has more than 20 printers. The cost of one based on the simplest technology ranges from $300 to $1000. This year, the company purchased a Polish-made SLS printer that prints with powder. It gives the most durable and high-quality parts. The price of such equipment is about 30,000 euros. In 3D printing, the production process is not a classic one, where one part is the same as the others. There are many variables, and it is important to gradually scale up," the speaker explains.

How did they start to produce for the military? On 24 February, the team gathered in the office and decided that the previous activities were now "a little bit" irrelevant. One of the employees went to serve as a reservist, and several others went to join the territorial defence for patrolling. Despite this, the core of the team remained.

"We decided: we will work in the field where we are superexperts. So on the first day the company became a hub that accepted orders for the needs of the Armed Forces. We called volunteers and the military, and asked what we could do. We helped to deliver humanitarian goods related to 3D printing," says Shulgan.

Production for the needs of the Ukrainian military began with two products, a tactical periscope and an Israeli bandage. "One set of plastic parts for the bandage took about three hours to print. At the same time, everything needed for the periscope was produced by one printer for about six hours," he recalls.

Now the company also co-operates as a contractor with several drone manufacturers. "We considered our own drone production, but decided not to focus on it because it is a sophisticated technology. It is better that such things are done by experts in these niches. And we will help them with our expertise in 3D printing in the manufacturing of prototypes or some parts," says Shulgan.

Why was the second production line launched? Military and volunteer requests over time increasingly began to be satisfied with conventional production methods. Shulgan explains that 3D printing is especially useful when you need to quickly produce a new design in small quantities. At the outset of the full-scale invasion, 3D printing in Ukraine was used as mass production because price did not play any role then. "Now mass production of the most necessary objects is either established or they are imported to Ukraine from abroad, and 3D printing is now used exclusively for the design of some new products – to launch them into operation," the speaker adds.

He says that the Israeli bandage required sewing equipment, as the plastic elements that were printed on the printer were sewn together with a flexible bandage and a special plate. This was the reason for the opening of another department that creates military equipment not only using 3D printing methods, but also sewing equipment. "We produce a prototype on a 3D printer, then scale it up and connect sewing equipment," explains Shulgan.

At first, the company rented sewing machines, and people sewed as volunteers. Over time, production scaled up and the company rented a sewing workshop and hired employees. Now there are more than 20 employees engaged in sewing.

How did they set up the logistics chain? The supply of the necessary materials took about two to three weeks from the first request to the receipt of the order. "As soon as we saw that we were starting to run out of some material, we had to get in touch, find out what the situation was, and agree a little in advance. We understood that we would not be able to get the material at any second," Shulgan notes.

He says that logistics is complicated by the lack of direct supplies from China, as materials are imported through Europe. Chinese printers and equipment need preventive maintenance more often than others. "We have many brands of equipment, and although some of them have the Chinese manufacturer, their warehouses are in Europe, so there are no aspects with this. And there is some equipment that we can't even handle, because it is impossible to get the accessory components," he explains.

Intermediate results. Now the company has already provided the front line with about 5000 different orders. "It is difficult to give an exact figure, because we did not keep accurate records. Until June we did not focus on this at all. There were different orders, they all came in waves. For example, there was a request for aerial reconnaissance, which we worked on for several weeks. In fact, 20 printers worked for one project," Shulgan clarifies.

If you have read this article to the end, we hope that means it was useful for you.

We work to ensure that our journalistic and analytical work is of high quality, and we strive to perform it as competently as possible. This also requires financial independence. Support us for only UAH 196 per month.

Become a Mind subscriber for just USD 5 per month and support the development of independent business journalism!

You can unsubscribe at any time in your LIQPAY account or by sending us an email: [email protected]